Neodymium Magnet

NdFeb has the best performance among the rare-earth permanent magnets. It is the rare earth permanent magnet with the strongest magnetic property at present. It has an extreme high BH max and good Hcj, and greatly machinability. It is the most widely used permanent magnet material in the industrial field and known as the “Magnet King”.

Samarium Cobalt Magnets

The main raw materials of SmCo permanent magnets are samarium and cobalt rare earth elements. SmCo magnet is the alloy magnet which produced through Power Metallurgy technology that is made into a blank by Melting, Milling, Compression Molding, Sintering, and Precision Machining.

Alnico Magnet

Alnico Magnet is the alloy magnet of Aluminum, Nickel, Cobalt, Iron and other trace metal elements, which is the first generation of permanent magnet materials that developed at the earliest.

Magnetic Assembly

Magnetic Assembly is an important link to realize the function of magnetic materials. It is mainly a product or semi-finished product that realizes its application function after magnetic materials with metal, non-metal and other materials with specific requirements for assembly. Xinfeng Magnetic Materials Co., Ltd. specializes in the research, development and production of magnetic devices. The main products include magnetic suction parts, promotional magnetic gifts, magnetic nameplates, magnetic suckers, magnetic suction, permanent magnet lifters, magnetic tools and other magnetic components. We can also provide customers with a variety of industrial permanent magnet coupling, motor permanent magnet fixed rotor, multi-piece adhesive magnets and components, as well as Helbeck array and other magnetic assembly for research and development.

Rubber Magnet

As a composite material, Rubber Magnet is made by mixing ferrite powder with rubber and finished through extrusion or rolling.

Rubber Magnet is highly flexible in itself, which can be used to produce special-shaped and thin-walled products. The finished or semi-finished product can be cut, punched, slitted or laminated tailed to specific need. It is high in consistency and precision. Good performance in impact resistance makes it non-breakable. And it has good resistance to demagnetization and corrosion.

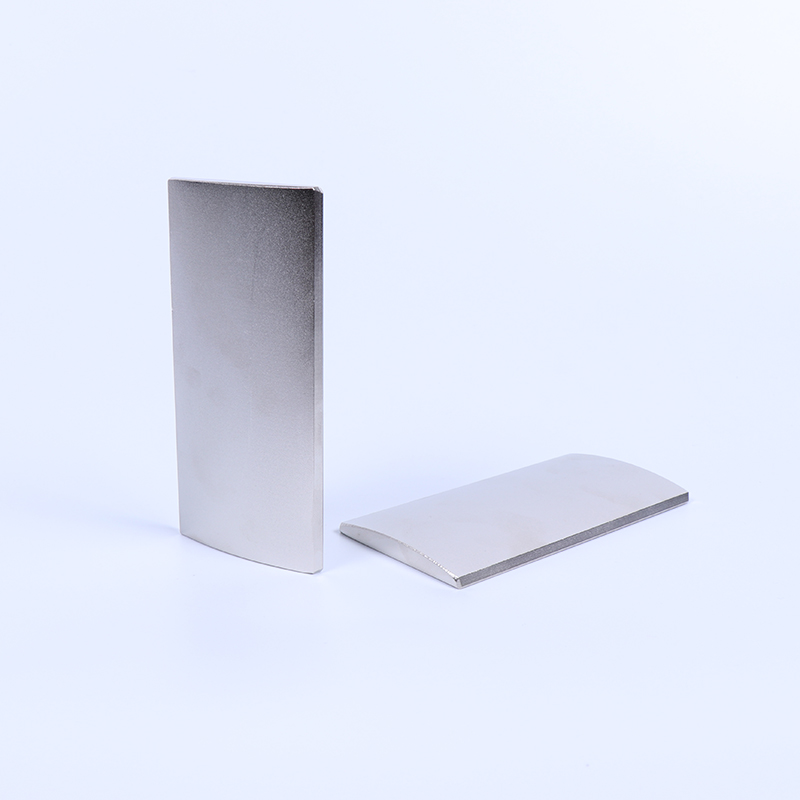

Lamination Magnet

Laminated rare earth magnets can reduce eddy current losses in high-efficiency motors. Smaller eddy current losses mean lower heat and higher efficiency.

In permanent magnet synchronous motors, the eddy current losses in the rotor are ignored because the rotor and stator are rotating synchronously. In fact, stator slot effects, non-sinusoidal distribution of winding magnetic forces and harmonic magnetic potentials generated by harmonic currents in the coil winding also cause eddy current losses in the rotor, rotor yoke and metal permanent magnets binding the permanent magnet sheath

Since the maximum operating temperature of sintered NdFeB magnets is 220 ° C (N35AH), the higher the operating temperature, the lower the magnetism of the NdFeB magnets, the lower the conversion and power of the motor. This is called heat loss! These eddy current losses can lead to elevated temperatures, leading to local demagnetization of permanent magnets, which is particularly severe in some high speed or high frequency permanent magnet synchronous motor.

Neodymium Magnet with Thread

Magnetic assembly include magnetic alloys and non-magnetic materials. Magnet alloys are so stiffness that even simple features are difficult to incorporate into the alloys. Installation and application specific features are easily incorporated into non-magnetic materials that normally form shell or magnetic circuit elements. The non-magnetic element will also buffer the mechanical stress of the brittle magnetic material and increase the overall magnetic strength of the magnet alloy.

Magnetic assembly usually have a higher magnetic force than general magnets because the flux conducting element (steel) of the component is usually an integral part of the magnetic circuit. By using magnetic induction, these elements will enhance the magnetic field of the component and focus it to the area of interest. This technique works best when magnetic components are used in direct contact with the workpiece. Even a small gap can greatly affect the magnetic force. These gaps can be actual air gaps or any coating or debris that separates the component from the workpiece.

Magnetic Coupling

Magnetic coupling is a coupling that transmits torque from one shaft, but it uses a magnetic field rather than a physical mechanical connection.

Magnetic couplings are often used in hydraulic pump and propeller systems because a static physical barrier can be placed between the two shafts to separate the fluid from the air operated by the motor. Magnetic couplings do not allow the use of shaft seals, which will eventually wear out and align with system maintenance, because they allow greater off-shaft error between the motor and the driven shaft

Magnetic Chuck

Characteristics of pot magnet

1.Small size and powerful function;

2.The strong magnetic force is only concentrated on one side, and the other three sides have almost no magnetism, so the magnet is not easy to break;

3.The magnetic force is five times than that of the same volume magnet;

4.Pot magnetic can be freely adsorbed or easily removes from the hardware;

5.Permanent NdFeb magnet has a long service life.

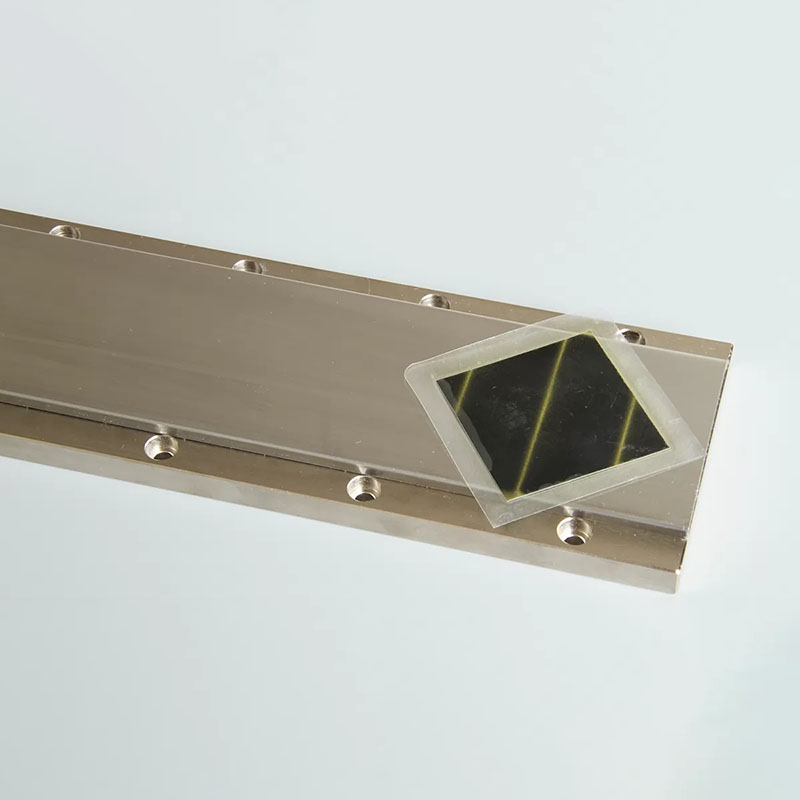

Magnet Linear Motor

A linear motor is an electric motor that has had its stator and rotor "unrolled" so that instead of producing a torque(rotation) it produces a linear force along its length. However, linear motors are not necessarily straight. Characteristically, a linear motor's active section has ends, whereas more conventional motors are arranged as a continuous loop.

Motor Magnetic Rotor

Rare earth permanent magnet motor is a new type of permanent magnet motor, which started in the early 1970s. Rare earth permanent magnet motor has a series of advantages such as small size, light weight, high efficiency and good characteristics. Its application is very wide, involving aviation, aerospace, national defense, equipment manufacturing, industrial and agricultural production and daily life and other fields.

We mainly produce magnetic components in the field of permanent magnet motors, especially NdFeb permanent magnet motor accessories, which can match all kinds of small and medium permanent magnet motors. In addition, in order to reduce the damage of electromagnetic eddy current to the magnet, we made multiple spliced magnets.

Customized Magnets

According to the specific and special requirements of customers, we provide one-to-one design and brand selection of rare earth magnets.

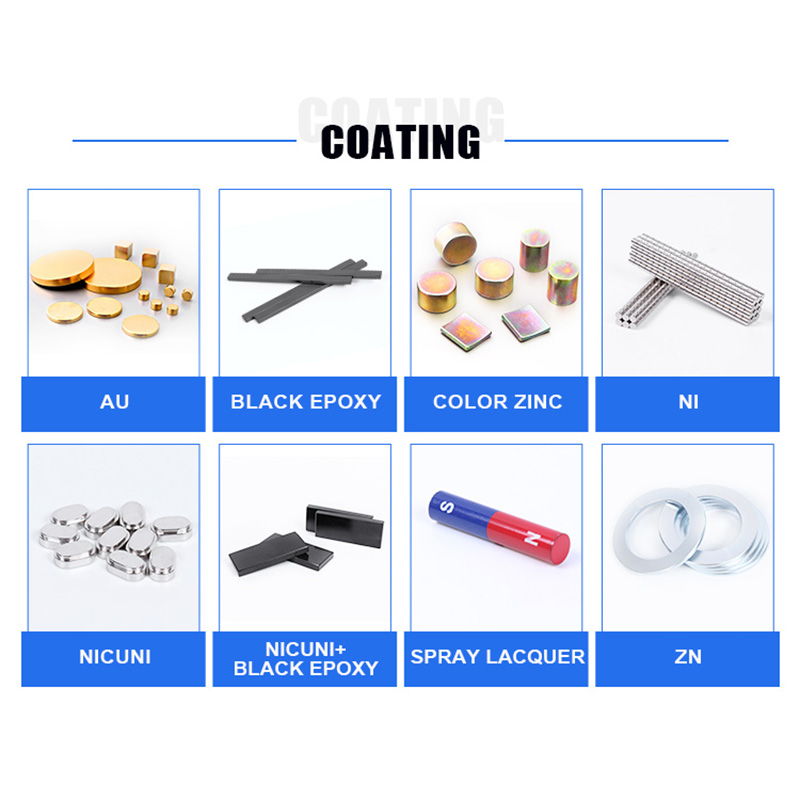

From the magnetic properties of rare earth permanent magnet (surface magnetism, flux/magnetic moment, temperature resistance), mechanical properties, as well as physical and chemical properties, to the surface coating properties and adhesive properties of magnets and related soft magnetic materials, we provide you with the most cost-effective magnetic solutions.

Application of Magnets

The company's products are mainly used in the fields of new energy vehicles and auto parts, and the downstream application fields are broad. They are in line with the energy-saving and environmental protection concepts vigorously advocated by the country, helping the country to achieve the goal of "carbon neutrality", and market demand is growing rapidly. The company is the world's leading supplier of magnetic steel in the field of new energy vehicles, and this field is the company's key development direction. At present, the company has entered the supply chain of a number of leading companies in the global automotive industry, and has obtained a number of international and domestic automotive customer projects. In 2020, the company's sales volume of magnetic steel products was 5,000 tons, an increase of 30.58% over the same period last year.

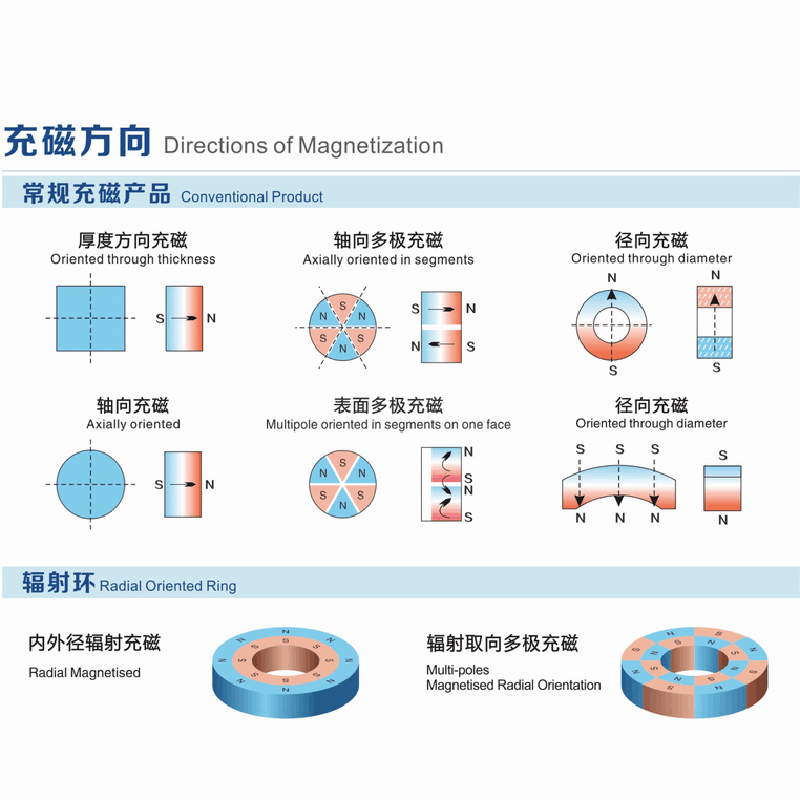

Magnetization Direction

The orientation process of magnetic materials in the production process is the anisotropic magnet. Magnet is generally molded with magnetic field orientation, so it is necessary to determine the orientation direction before the production, that is the magnetization direction of the products.

Electroplating Analysis

REMARKS

1. SST Environment: 35±2℃,5%NaCl,PH=6.5-7.2,Salt spray sinking 1.5ml/Hr.

2. PCT Environment: 120±3℃,2-2.4atm, distilled water PH=6.7-7.2 , 100%RH

PLEASE CONTACT US FOR ANY SPECIAL REQUESTS

Products Knowledge

A: Main magnetic performances include remanence(Br), magnetic induction coercivity(bHc), intrinsic coercivity(jHc), and maximum energy product (BH)Max. Except those, there are several other performances: Curie Temperature(Tc), Working Temperature(Tw), the temperature coefficient of remanence(α), temperature coefficient of intrinsic coercivity( β), permeability recovery of rec(μrec) and demagnetization curve rectangularity(Hk/jHc).

……………………